The main goal of 3D mapping is to turn raw, mathematical dimensional data into a complete digital asset that looks and works exactly like the real thing. This process goes beyond just capturing geometry. It uses color, material properties, and texture smartly on the surface of a scanned object to make a “digital twin” that is very realistic. Because of this, 3D mapping is used in a wide range of modern professional fields, from making and inspecting industrial products to making realistic digital content and custom medical devices. The advanced features of specialized 3D mapping software, like the ones made by 3DeVOK, which are made to seamlessly combine high-precision geometry with photorealistic surface data, are what make these fields successful. The mapping stage is the most important part of the digitization pipeline because it creates the digital models that are used for analysis, visualization, simulation, and eventually, physical production.

Industrial Accuracy in Quality Control and Reverse Engineering

3D mapping provides essential visual and analytical capabilities for key industrial tasks. In reverse engineering, it transforms scanned data of existing components into clean, CAD-ready polygon meshes, accurately capturing complex geometries for design refinement.

For quality control, the technology enables rapid comparison of manufactured parts against original CAD designs through color-coded deviation maps, visually highlighting dimensional variances to accelerate inspection and identify production issues early.

The software also processes large-scale scan data from industrial facilities, documenting as-built conditions of structures, pipelines, and equipment layouts to support retrofit planning and maintenance. Specialized systems like 3DeVOK deliver the processing power required to precisely align and measure these complex industrial environments.

Archival Fidelity for Digital Assets and Cultural Heritage

Artists, cultural institutions, and digital content creators all use 3D mapping to capture and store the visual essence of real-world objects. In Cultural Heritage and Museum Digitization, 3D mapping keeps artifacts, sculptures, and architectural features safe for future generations. The scanning doesn’t touch the objects, which is important for keeping them safe. The 3D Mapping Software makes sure that the scans are of archival quality by taking care of both the detailed geometry and the important visual information. This is possible because of advanced color and texture processing, which accurately captures details on the surface like paint flaking, corrosion, or fine carving marks. These mapped models are used for academic research, virtual museum exhibits, and careful planning for digital restoration.

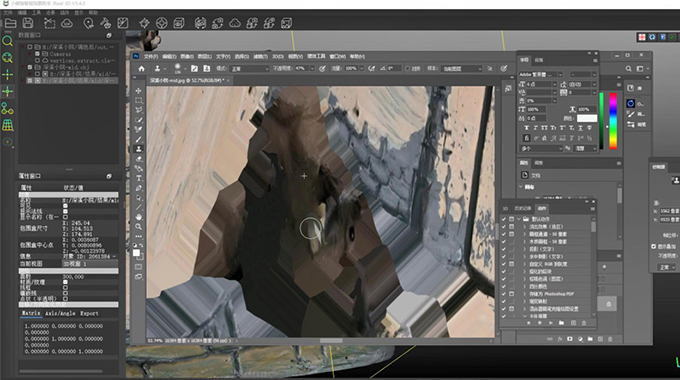

In addition, the technology is very important for making Digital Assets for Virtual Display and for the entertainment industry. This includes making very realistic Digital Humans for movies and video games or making detailed product models for marketing and online shopping. To get this level of photorealism, you often need to use the advanced technique of Texture Mapping Replacement. This is a feature of specialized 3D texturing software that uses math to project high-resolution photos taken separately from the geometric scan onto the mesh. This kind of 3D projection mapping software makes sure that the visual detail is as good as a DSLR camera and fits perfectly over the scanner’s high-precision shape. The 3DeVOK platform is great for this kind of integration because it has its own mapping tools that make assets that look great and work well in virtual reality (VR), augmented reality (AR), and computer animation.

Advanced Uses in Simulation and Custom Design

Beyond traditional engineering, 3D mapping plays a vital role in specialized fields such as healthcare and advanced design. In medical rehabilitation, eye-safe scanners capture precise anatomical data, which 3D mapping software converts into accurate digital models for custom prosthetics and orthotics. This capability to process complex organic shapes ensures perfect fitting, significantly reducing the time and cost associated with traditional physical molding methods.

The technology also enables sophisticated engineering analysis through simulation and predictive modeling. Mapped models are imported into FEA or CFD software to simulate real-world conditions like stress distribution or thermal performance. The high accuracy of systems like 3DeVOK ensures these simulations produce reliable results, helping engineers predict part failure and optimize designs before physical testing.

Furthermore, 3D mapping directly supports rapid prototyping and manufacturing. The software prepares optimized models for 3D printing, enabling quick conversion of digital designs into physical prototypes for accelerated product testing and iteration cycles.

How 3DeVOK Helped Unlock Mapping Potential

To sum up, 3D mapping is the main processing layer that turns raw 3D scan data into something useful. There are no limits to its uses because different fields need it to be accurate, fast, and visually accurate. The quality of the final digital asset depends on how reliable and smart the 3D Mapping Software is, whether it’s making industrial parts that can handle a lot of stress, preserving priceless cultural artifacts, or making immersive digital environments with 3D projection mapping software. 3DeVOK offers this all-in-one, fully integrated solution that makes the switch from a physical object to a professional, high-fidelity digital twin smooth and works well with even the most demanding professional workflows.