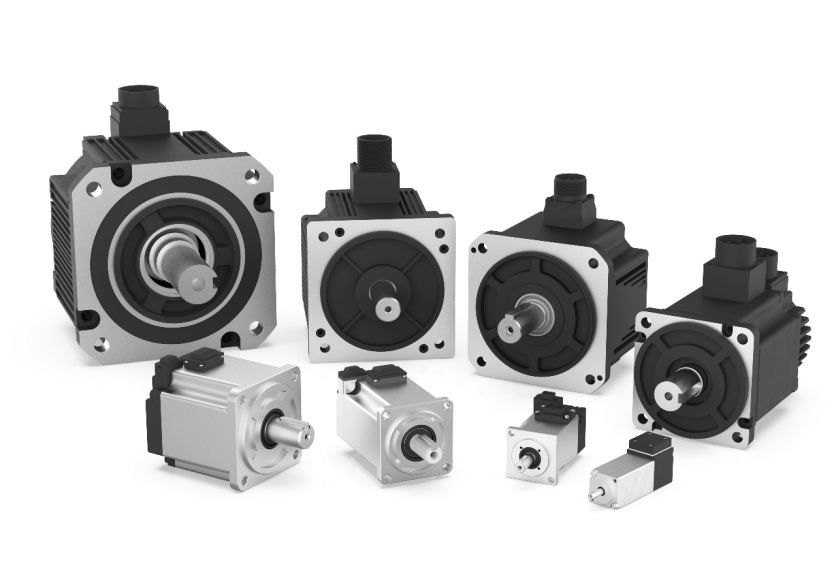

In the sophisticated realm of modern manufacturing, precise motion control is the foundation of efficiency. Whether it is a robotic arm assembling microchips or a CNC machine carving aerospace components, the ability to move a mechanism to an exact position at a specific speed is paramount. The device responsible for this high-level performance is the industrial servo motor. Unlike standard motors that simply spin when power is applied, these advanced actuators operate within a closed-loop system to provide intelligent, feedback-driven motion. Leading manufacturers like Leadshine have refined this technology, producing motors that serve as the heartbeat of automation systems worldwide.

The Fundamental Architecture of a Servo

At a hardware level, an industrial servo motor shares similarities with standard electric motors but is built with higher-grade materials and tighter tolerances. The core consists of a stationary stator wound with copper coils and a rotating rotor equipped with high-strength permanent magnets. When electrical current flows through the stator windings, it creates a magnetic field that interacts with the rotor’s magnets, causing rotation. However, what distinguishes a Leadshine servo motor, such as those in the ELM series found on their product page, is the design focus on minimizing “cogging” (jerkiness) and maximizing torque density. This ensures that the motor delivers smooth, continuous rotation even at very low speeds.

The Critical Role of the Feedback Device

The defining feature of any servo system is the feedback mechanism. Mounted on the rear shaft of every industrial servo motor is a sensor known as an encoder. This device acts as the “eyes” of the system. As the motor spins, the encoder tracks its position, speed, and direction in real-time. Leadshine equips their high-performance motors with 23-bit multi-turn absolute encoders. To put this precision in perspective, a 23-bit encoder splits a single revolution into over 8 million distinct counts. This immense resolution allows the system to detect and correct positional errors that are invisible to the naked eye, ensuring the final output is accurate to the micrometer.

The Closed-Loop Control System

An industrial servo motor does not operate in isolation; it works in tandem with a servo drive. The operation relies on a continuous conversation between these two components. The drive sends a command to the motor (e.g., “move 100 degrees”). The motor begins to move, and the encoder immediately reports the actual progress back to the drive. The drive compares the “commanded position” vs. the “actual position” thousands of times per second. If there is any discrepancy—caused by friction, gravity, or external load—the drive instantly adjusts the current to correct the error. This “closed-loop” architecture is what gives the servo its legendary accuracy and stiffness.

Achieving High Torque Density

One of the primary demands in heavy industry is the need for power in a compact package. This is where the high torque servo motor excels. Through the use of rare-earth neodymium magnets and optimized winding techniques, these motors can generate substantial force relative to their size. On the Leadshine product page, the ELM and ELM2 series are highlighted for their high power density. This capability allows machine builders to use smaller motors to drive heavier loads, saving valuable space in the machine design. A high torque servo motor is particularly crucial in applications like injection molding or metal pressing, where the motor must hold a heavy load steady against significant resistance.

Dynamic Response and Overload Capacity

Industrial processes often require rapid changes in speed and direction. A standard motor takes time to spin up and slow down, but an industrial servo motor is designed for high dynamic response. It has a low moment of inertia, allowing it to accelerate from zero to thousands of RPM in milliseconds. Furthermore, these motors are built to withstand significant temporary overloads. It is common for a Leadshine servo motor to handle 300% of its rated torque for short bursts. This “peak torque” capability is essential for overcoming the initial inertia of a stationary load or handling momentary spikes in resistance without stalling or losing synchronization.

Thermal Management and Durability

Working hard generates heat, and heat is the enemy of electronics. Effective thermal management is integral to how these motors function. The stator design of a Leadshine motor is optimized to dissipate heat efficiently through the housing fins. Additionally, because the closed-loop system only draws the current necessary to move the load (unlike stepper motors which run at full power), servo motors run significantly cooler. This efficiency extends the lifespan of the internal components, particularly the bearings and the insulation of the windings. For harsh environments, the product page notes that many of these motors come with IP67 protection ratings, meaning they are sealed against dust and liquid ingress, ensuring the internal physics remain undisturbed by external contaminants.

Versatility in Application: AC and DC Options

While the operating principles remain similar, the power source can vary. Leadshine offers both AC and DC servo solutions to match different infrastructure needs. The high-voltage AC servos (operating on 220VAC or 400VAC) are the standard for stationary factory equipment requiring high power. Conversely, for mobile applications like Automated Guided Vehicles (AGVs), a Low Voltage DC high torque servo motor is used. These operate on battery voltages (24-60VDC) but still utilize the same sophisticated feedback loops to ensure the robot navigates precisely. This versatility allows engineers to apply servo technology across every stage of the production floor, from the heavy assembly line to the mobile logistics robots.

The Heart of Precision

In summary, an industrial servo motor works by combining robust electromagnetic mechanics with high-resolution digital feedback. It is a device that constantly monitors its own performance, making micro-adjustments to ensure reality matches the command. Whether it is a compact unit or a large high torque servo motor, the technology represents the pinnacle of motion control. Companies like Leadshine continue to push the boundaries of what these motors can do, offering higher resolutions, better protection, and greater efficiency. For any industry seeking to automate complex tasks with speed and precision, understanding and utilizing these advanced motors is the key to success.